Design Services

Precision Mold Design Delivered Fast

We provide accurate mold designs faster than ever using the latest CAD software and updated hardware. Our expert engineers deliver high-quality designs and innovative solutions, helping customers maximize production time and stay ahead in mold design and engineering.

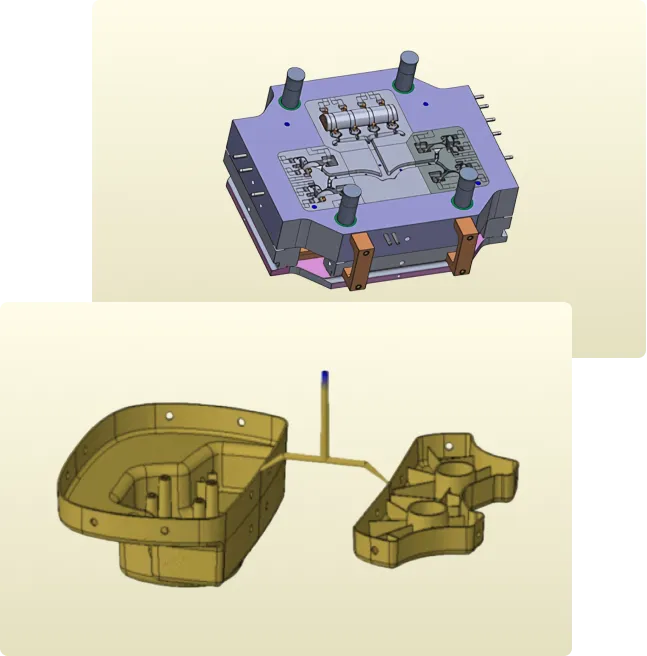

Smart Tooling Solutions

Choosing the right tooling for your application depends on part size, complexity, design confidence, materials, lifecycle, and demand. The Design team will evaluate these factors to recommend the best solution. Interchangeable insert molds add versatility, while multi-cavity molds and hot-feed systems improve efficiency in high-volume runs. For small volumes or similar parts, MUD mold systems are effective. With costly materials, innovative tooling design can minimize waste and control expenses.

We Bring Your Big Ideas to Life

DesEngin takes your project from concept to completion with expertise in mold and plastics industries. We provide precision engineering, injection molding, advanced tooling, and full manufacturing services—tailored solutions to meet your industry’s specific needs.

How it works

We analyze your needs—function, look, budget, volume—to ensure the product design meets your goals.

Design Check

Ensuring cost-effective, efficient, and quality-ready product designs optimized for molding.

Smart Design

Materials are chosen based on intended use, functional needs, and forming process requirements.

Smart Materials

A prototype tests functionality and appearance to ensure design meets production and user needs.

Prototype Lab

We analyze your needs—function, look, budget, volume—to ensure the product design meets your goals.

Design Check

Ensuring cost-effective, efficient, and quality-ready product designs optimized for molding.

Smart Design

Materials are chosen based on intended use, functional needs, and forming process requirements.

Smart Materials

A prototype tests functionality and appearance to ensure design meets production and user needs.

Prototype Lab

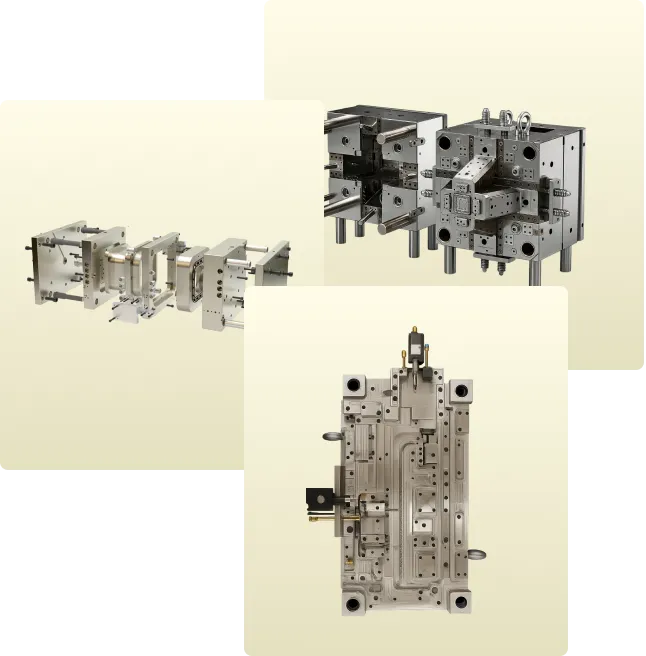

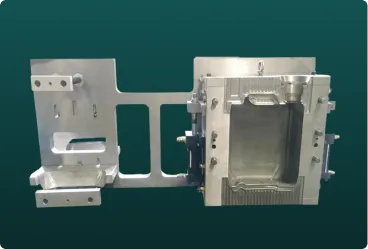

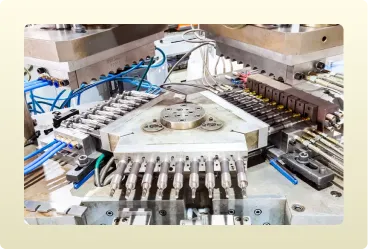

Injection Mold Design

DesEngin offers custom mold design services with 18+ expert engineers. We use CAD/CAM, 3D simulation, and DFMEA to ensure precise, risk-free molds. We work closely with clients to align mold specifications with product goals and manufacturing needs, backed by years of experience.

Single Cavity

Fast, precise injection mold designs for large parts—high quality, short cycles, lower cost.

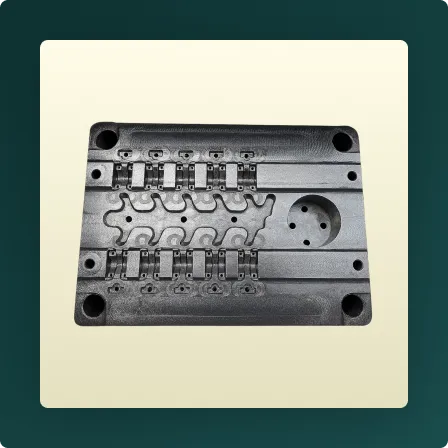

Multi Cavities Multi Parts

We design multi-gap molds for high-volume production, maximizing injection press efficiency.

Multi Cavities Same Part

We design multi-gap molds for high-volume production, maximizing injection press efficiency.

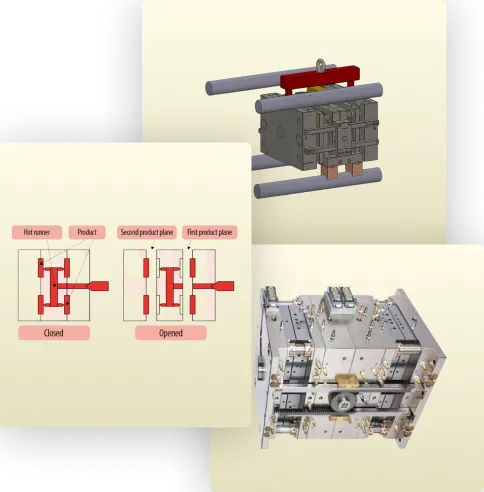

Stack Mold

Stacked injection molding boosts efficiency with multiple cavities, doubling production output.

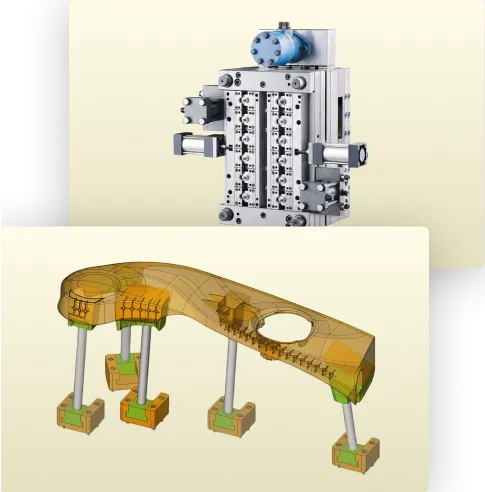

Unscrews & Undercut

Injection molded parts with threads require innovative mold release

solutions.

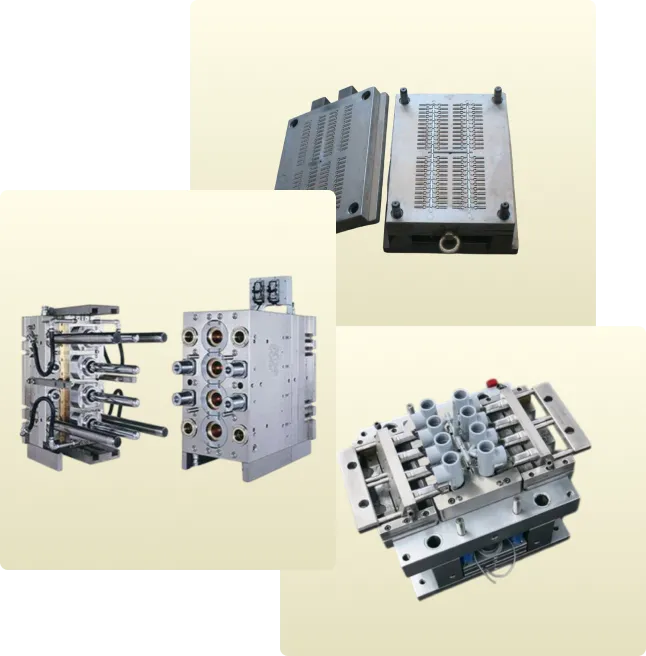

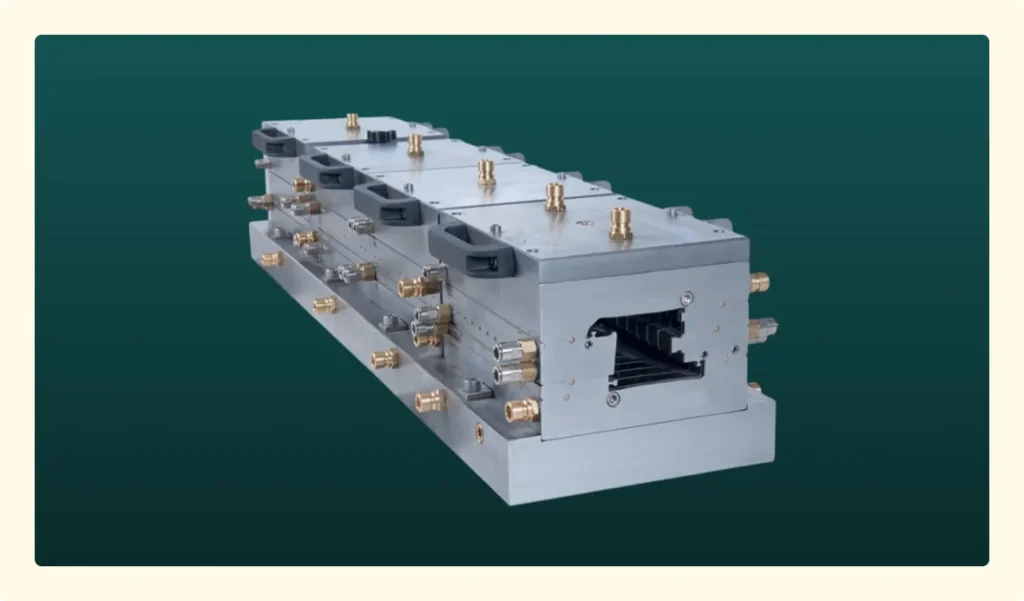

Blowing Mold Design

We provide single- and multi-cavity blow molds with precise cooling and thermal balance for stable, high-quality production. Our designs focus on optimal metals and processing at cutting and separation lines to ensure professional, accurate, and durable end products.

Single Cavity

Multi Cavities

1-Cavity, Movable-Head

Blow Mold + Deflash

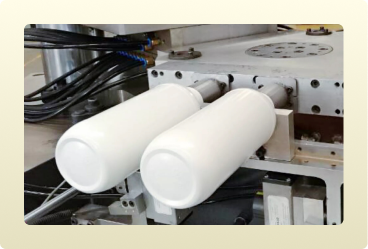

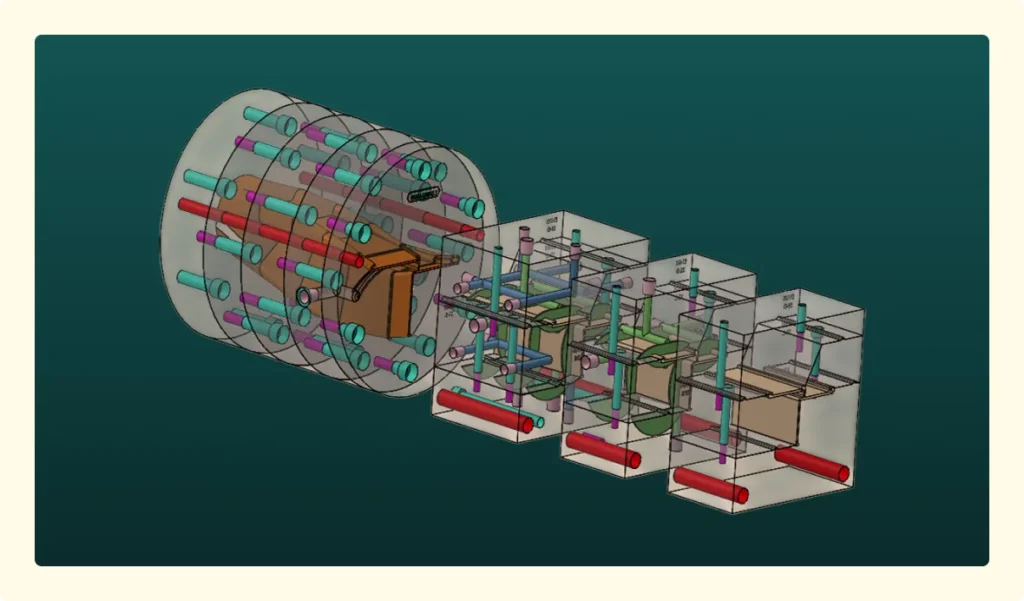

Injection Blowing Design

Blow-molded plastic products often need precise neck details like wall thickness and threading, which blow molding alone can't provide. That’s why injection-blow molding is used—either semi-automatic (two machines) or automatic (injection and blowing in one machine).

2-Cav. Inj. Blow Mold

5-Cav. Inj. Blow Mold

6-Cav. Preform Blow Mold

9C 3S direct inj. blow

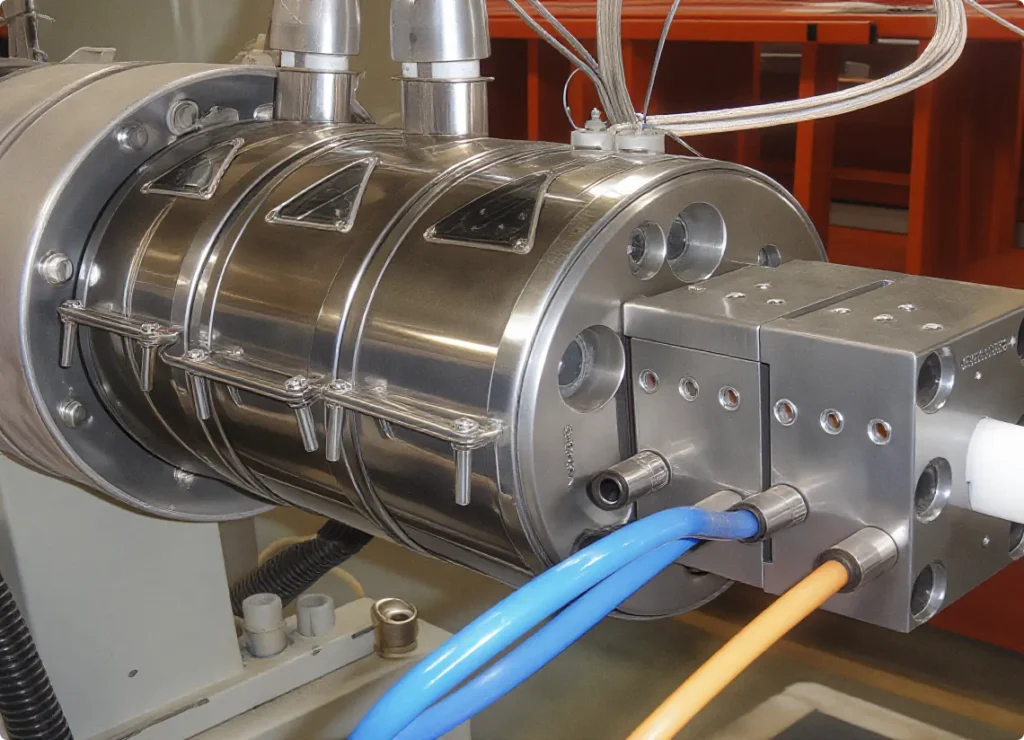

Extrusion Tool Design

At DesEngin , we design precise tools by studying plastic behavior under pressure and temperature changes, from melting to solidifying. Our team focuses on flow, sealing, and cooling stages to deliver reliable, accurate mold designs tailored to each project's unique challenges.

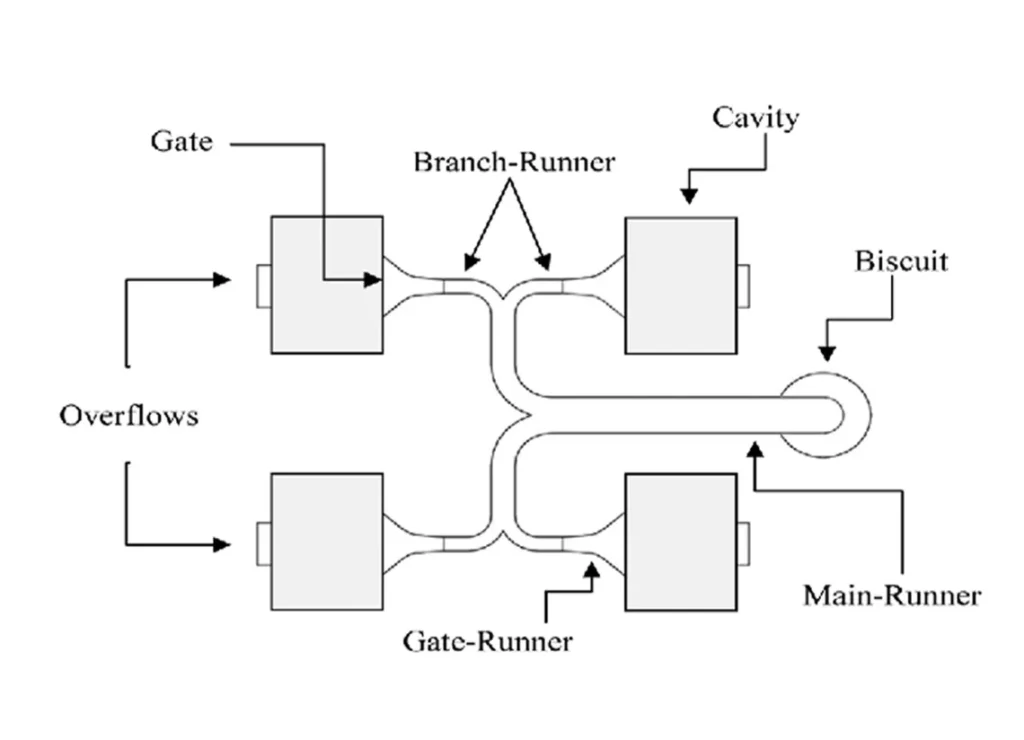

Casting Mold Design

We design high-precision metal casting molds for aluminum and antimony parts, ensuring accurate shapes and performance. Our service helps clients save time by centralizing design in one office, with careful attention to temperatures, pressures, and product details.

solid soap Forming molds

DesEngin offers a professional and efficient solid soap mold design service, whether your cooling system uses ammonia or other refrigerants.

Bringing Your Vision to Reality

At DesEngin , we combine 40+ years of engineering expertise with innovative design solutions tailored for the U.S. market. From mold design to full product development, our team is ready to help you create efficient, reliable results that match your business goals